Introduction to CPG Packaging

In the highly competitive world of consumer packaged goods (CPG), packaging plays a crucial role in the success of products. Not only does it protect the product, but it also communicates the brand’s message and values to the consumer. A vital element in ensuring effective packaging is the meticulous definition of product specifications. These specifications are essential in maintaining quality, meeting regulatory standards, and optimising production processes. This article explores why product specifications are vital for CPG packaging and how they can be effectively managed using advanced tools like 4Pack.

Understanding CPG Packaging

CPG packaging refers to the packaging of goods that consumers use daily and need to replace frequently, such as food, beverages, personal care items, and household products. Packaging of consumer goods must be designed to be attractive, functional, and compliant with various regulatory standards.

Role of Packaging in the Consumer Packaged Goods Industry

Packaging in the CPG industry serves multiple purposes. It protects products during transportation and storage, provides essential information to consumers, and enhances the overall consumer experience. Effective packaging can differentiate a product from competitors on crowded retail shelves, influencing purchasing decisions.

The CPG packaging industry is continually evolving with new trends and innovations. Sustainable packaging, smart packaging with embedded technology, and customisable packaging solutions are some of the recent trends driving the industry forward. These innovations aim to meet consumer demands, improve efficiency, and reduce environmental impact.

The Role of Product Specifications in CPG Packaging

What Are Product Specifications?

Product specifications are detailed documents that outline the requirements for a product’s design, materials, dimensions, and performance. These specifications ensure that all aspects of the product and its packaging meet the intended standards and functionality.

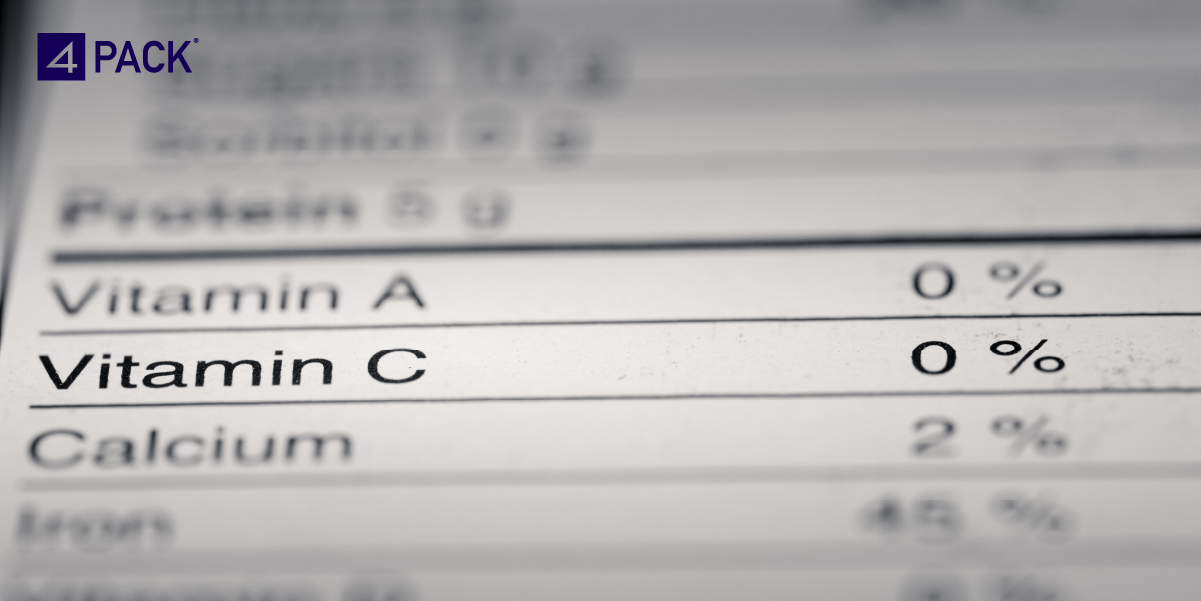

Product specifications typically include material descriptions, design guidelines, size and weight parameters, safety and compliance requirements, and any other relevant details that ensure the product meets quality and regulatory standards.

Why Product Specifications Matter In CPG Packaging

- Ensuring Consistency and Quality: Having well-defined product specifications ensures consistency and quality across all production batches. It helps maintain the integrity of the product and its packaging, ensuring that each unit meets the brand’s standards.

- Regulatory Compliance: Product specifications are crucial for complying with regulatory requirements. They ensure that the packaging meets legal standards for safety, labelling, and environmental impact, avoiding costly fines and recalls.

- Cost Efficiency and Waste Reduction: Clear specifications help streamline production processes, reducing waste and improving cost efficiency. They enable manufacturers to optimise material usage and minimise errors that can lead to costly rework.

Key Elements of Product Specifications for CPG Packaging

Material Specifications

Various materials are used in CPG packaging, including plastics, paper, glass, and metals. Each material has its properties and suitability depending on the product’s requirements.

With increasing consumer awareness of environmental issues, sustainability has become a crucial consideration in packaging. Product specifications should include guidelines for using recyclable or biodegradable materials to reduce environmental impact.

Design Specifications

Design specifications ensure that the packaging aligns with the brand’s identity and appeals to consumers. They include details on colours, fonts, logos, and overall aesthetic.

Functional design elements such as easy-open features, resealable closures, and tamper-evident seals are crucial for consumer convenience and product safety.

Size and Weight Specifications

Size and weight specifications ensure that the packaging is practical for storage, transportation, and retail display. They include standard dimensions that the packaging must adhere to.

Well-defined size and weight specifications help optimise shipping and handling processes, reducing costs and improving efficiency.

Safety and Compliance Specifications

Safety and compliance specifications ensure that the packaging meets all necessary regulatory requirements, including those related to health, safety, and environmental standards.

These specifications also consider consumer safety, ensuring that the packaging does not pose any risk to the user and complies with all safety standards.

Benefits of Well-Defined Product Specifications In CPG Packaging

- Improved Production Processes: Clear product specifications streamline manufacturing processes by providing precise guidelines for production, reducing errors, and improving efficiency.

- Reduced Errors and Rework: Detailed specifications minimise the risk of errors and the need for rework, saving time and resources.

- Meeting Consumer Expectations: Consistent product quality is essential for meeting consumer expectations and building trust in the brand.

- Building Brand Loyalty: High-quality, consistent products help build brand loyalty, encouraging repeat purchases and positive word-of-mouth.

- Better Supply Chain Management: Product specifications facilitate better coordination with suppliers, ensuring that materials meet the required standards and are delivered on time.

- Inventory Management and Forecasting: Clear specifications help with inventory management and forecasting, ensuring that the right materials are available when needed and reducing the risk of stockouts or overproduction.

Challenges in Defining Product Specifications

Balancing Cost and Quality

Balancing cost and quality is a common challenge in defining product specifications. A thorough cost-benefit analysis can help determine the optimal balance between the two.

Material and Production Costs

Selecting materials and production methods that meet quality standards without exceeding budget constraints is crucial for maintaining profitability.

Keeping Up with Regulatory Changes

Staying compliant with international standards can be challenging, especially for companies operating in multiple markets with varying regulations.

Compliance Documentation

Maintaining up-to-date compliance documentation is essential for demonstrating adherence to regulatory standards and avoiding legal issues.

Managing Changes and Updates

Effective version control is necessary to manage changes and updates to product specifications, ensuring that all stakeholders are working with the latest information.

Communication with Stakeholders

Clear communication with all stakeholders is crucial for managing changes and updates to product specifications, ensuring that everyone is informed and aligned.

Best Practices for Creating Effective Product Specifications In CPG Packaging

- Collaboration and Communication: Involving key stakeholders in the specification development process ensures that all perspectives are considered and that the final specifications meet all requirements.

- Cross-Functional Teams: Forming cross-functional teams that include members from design, production, marketing, and regulatory departments can help create comprehensive and effective product specifications.

- Detailed and Clear Documentation: Using standard templates and adhering to industry standards can help ensure that product specifications are clear, detailed, and consistent.

- Including Visual Aids: Including visual aids such as diagrams and illustrations can help clarify complex specifications and improve understanding.

- Regular Review and Updates: Implementing continuous improvement processes ensures that product specifications are under regular review and updated to reflect new insights and changing requirements.

- Feedback Mechanisms: Establishing feedback mechanisms allows for ongoing input from stakeholders, helping to identify areas for improvement and ensuring that specifications remain relevant and effective.

Recap

Product specifications are vital for effective CPG packaging. They ensure consistency, quality, regulatory compliance, and cost efficiency. By leveraging advanced tools like 4Pack, companies can streamline their packaging processes, enhance collaboration, and stay ahead of industry trends.

Adopting best practices for creating and maintaining product specifications can help businesses achieve remarkable results, meet consumer expectations, and build strong brand loyalty.

Contact us today to learn more about our innovative solutions.