Introduction to Food Safety Packaging Regulations

In today’s fast-moving and highly regulated food industry, safety and compliance are more than legal necessities – they are critical pillars of consumer trust and business sustainability. Consumers now expect full transparency about the food they eat. From allergen declarations to shelf-life guidance, the packaging is the last line of defence before a product reaches a consumer’s hands. This means it must be flawless.

Packaging mistakes, especially those involving allergens or incorrect ingredient information, can lead to serious health risks. Moreover, such errors can attract fines, force expensive product recalls, and severely damage a company’s reputation. In an industry where reputation is everything, one slip-up can have long-lasting consequences.

This is where 4Pack comes in. Designed specifically for the needs of the food sector, 4Pack is a powerful digital solution that helps organisations manage complex product and packaging data. It not only ensures full compliance with food safety packaging regulations but also streamlines internal processes to boost overall efficiency.

What Are Food Safety Packaging Regulations?

Food safety packaging regulations refer to a comprehensive set of laws and standards intended to prevent contamination, ensure transparency, and protect public health. These rules govern how food is packaged, labelled, and presented to the market. They ensure that consumers receive accurate information and that the food is safe throughout its shelf life.

These regulations typically cover several key areas:

- Material Safety: Ensuring packaging materials do not contaminate food.

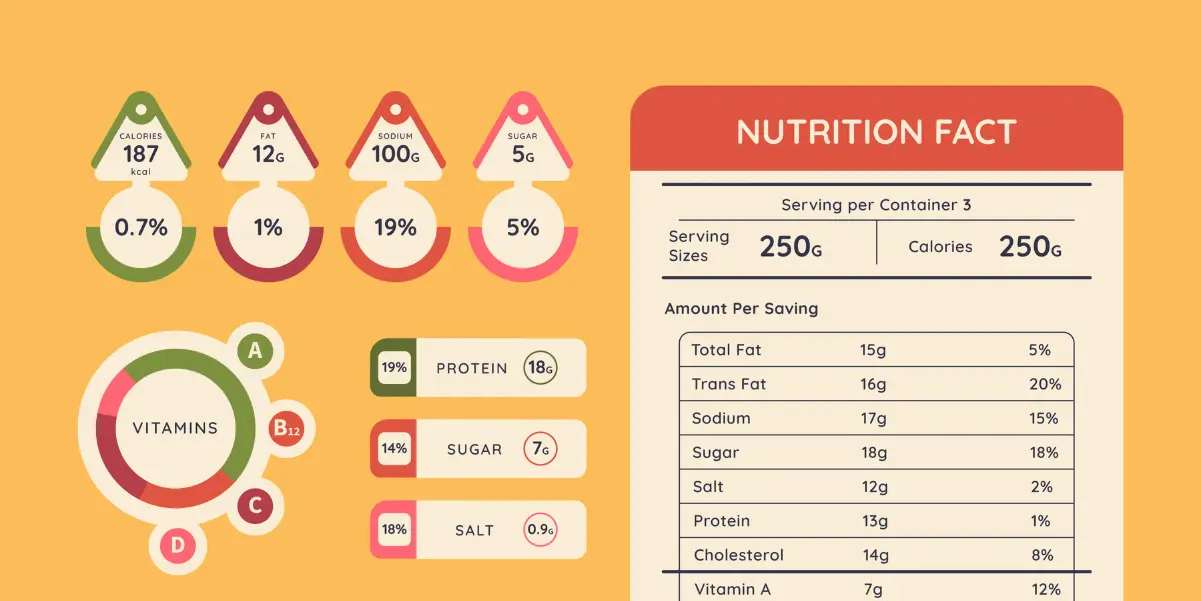

- Labelling Accuracy: Including all required nutritional data, ingredient lists, and usage instructions.

- Allergen Declarations: Clearly identifying the presence of allergens like peanuts, milk, soy, or gluten.

- Traceability: Providing a clear audit trail for every product.

Different regions have different authorities overseeing these rules:

- In the United States, the FDA (Food and Drug Administration) enforces standards under the Food Safety Modernization Act.

- In Europe, the EFSA (European Food Safety Authority) sets guidelines on food contact materials and labelling.

- In the UK, the FSA (Food Standards Agency) enforces food safety compliance.

- The Codex Alimentarius, developed by the FAO and WHO, offers globally recognised food safety standards.

Despite regional differences, the core principles remain the same: protect consumers and ensure transparency. However, managing overlapping and evolving requirements without a centralised system can be overwhelming.

The Cost of Non-Compliance

The financial and reputational consequences of failing to comply with packaging regulations are significant. Regulatory fines can run into millions of pounds, particularly in cases involving undeclared allergens or contamination. Beyond the financial impact, product recalls can damage supply chains, delay launches, and result in a loss of consumer confidence.

Consumers today are more vocal and informed. A labelling mistake that causes a health risk can quickly become a PR disaster, especially on social media. The reputational damage from a single incident can take years to repair. Additionally, non-compliance can impact relationships with retailers and distributors, who expect full regulatory adherence from their suppliers.

In short, non-compliance is not just a legal risk – it’s a serious threat to your brand and bottom line.

How 4Pack Supports Compliance With Food Packaging Safety Regulations

4Pack addresses these challenges head-on by offering a single, integrated platform for managing all your product and packaging specifications. This solution ensures that everyone in your organisation, from product development to marketing and regulatory teams, works from the same up-to-date information.

The software automates repetitive tasks, reduces the risk of human error, and provides built-in checks aligned with global regulations. The result is faster, more reliable compliance processes that give teams confidence and peace of mind.

Allergen Labelling Made Easy

Accurate allergen labelling is one of the most critical aspects of food safety. With 4Pack, allergen information is stored for each ingredient in a centralised digital repository. This database ensures that any updates to formulations are reflected instantly across all relevant packaging and labels.

The system removes the need for manual data entry, which is often the root cause of mislabelling errors. As soon as a change is made, 4Pack triggers automatic updates, so your labelling remains compliant and trustworthy. These automation features drastically reduce the likelihood of allergen-related incidents and potential recalls.

Packaging Approval and Traceability

4Pack enables teams to manage artwork, packaging designs, and approval workflows all in one place. Every revision is tracked through a robust version control system, so teams always work with the latest files. It ensures complete traceability, from initial design through to final approval.

Built-in rules and smart alerts help catch inconsistencies before they reach the market. Whether it’s a missing allergen label or an outdated ingredient list, the system flags the issue early. This proactive approach not only prevents costly mistakes but also saves time by avoiding last-minute changes.

Ready for Audit at Any Time

Audits are an inevitable part of food manufacturing. With 4Pack, businesses can respond to audit requests quickly and confidently. All compliance documentation, historical versions, and sign-off records are stored securely in the cloud. With just a few clicks, auditors and regulatory inspectors can access everything they need.

Role-based access ensures that only authorised personnel can make edits, adding a layer of accountability and security. This transparency builds trust both internally and with external regulators.

Boosting Efficiency Through Digitisation

Food companies operate in a high-pressure environment where delays and inefficiencies can impact market share. 4Pack improves internal workflows by digitising key processes such as recipe development, label creation, and specification management.

Instead of working across disjointed spreadsheets and emails, your teams can collaborate in real time within a single platform. This speeds up product development and reduces time to market.

Furthermore, 4Pack’s reporting and analytics tools allow you to monitor packaging performance, identify inefficiencies, and make data-driven decisions. By centralising information and automating reporting, businesses can respond more quickly to market changes and regulatory updates.

Seamless Integration

Adopting a new platform shouldn’t disrupt your existing operations. That’s why 4Pack is designed to integrate smoothly with your current ERP, PLM, and labelling systems. Through secure APIs, it connects with your existing tools to create a unified data environment.

Suppliers can also be given access through dedicated portals, improving visibility and collaboration across the supply chain. This ensures everyone involved in the packaging lifecycle is working from the same up-to-date information, further reducing the risk of error.

Beyond Compliance: Added Business Value

While compliance is essential, 4Pack offers benefits that go beyond regulatory requirements. By removing duplication and manual processes, teams become more productive and focused. Clear workflows mean fewer misunderstandings and delays, while the availability of real-time data empowers better decision-making.

Accurate and transparent labelling also builds consumer trust. In an age where shoppers scrutinise labels for allergens, ingredients, and sustainability claims, the ability to deliver clear and compliant information gives your brand a competitive edge.

Why Food Brands Trust 4Pack & Remain Compliant With Food Safety Packaging Regulations

4Pack has been built specifically for the food and beverage sector. Its features are tailored to meet the real-world challenges that food manufacturers face, from managing allergens to ensuring multilingual labelling across international markets.

The platform scales easily, making it suitable for global brands as well as SMEs. Its success across a wide range of businesses demonstrates its flexibility, reliability, and industry relevance.

Summary

Complying with food safety packaging regulations is no longer optional – it’s essential. But it doesn’t have to be a burden. 4Pack simplifies and strengthens your compliance processes through automation, centralised data, and collaborative workflows.

By using 4Pack, your business will not only meet current regulations but be prepared for future changes. Get in touch today to discover how 4Pack can transform your packaging compliance and give your team the tools they need to succeed.