INTRODUCTION

The Challenge of Version Control

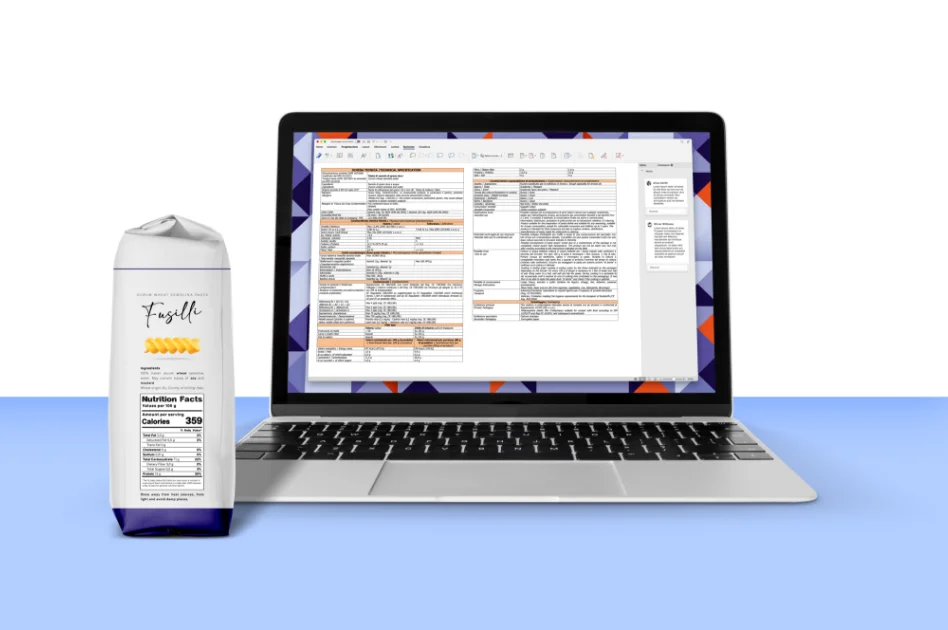

One of the major pain points in this process is the absence of automated version control. Without a robust system in place, teams are left vulnerable to errors and inconsistencies, especially as the complexity of SKUs and variants increases. However, at 4Pack, we have developed an innovative solution that tackles this challenge head-on.

Our version control software provides a comprehensive and efficient approach to managing and tracking changes, ensuring that all stakeholders have access to the most accurate and up-to-date information.

OUTCOME

Creating A Single Source For All Stakeholders

By implementing our version control software, we enable teams to centralise their product and packaging artwork and specifications, creating a single source of truth. This centralised repository serves as a reference point for all stakeholders, allowing them to collaborate seamlessly and take action on the most recent version.

Automatic version control ensures that everyone is aligned and working with the same information, eliminating confusion and reducing the risk of errors.

Moreover, our software allows for comments and rejections to be addressed while maintaining a detailed audit trail of changes. This means that each version is recorded and preserved, providing a transparent history of revisions and facilitating efficient decision-making.

SITUATION

Avoid Errors With Our Version Control Software

The process of launching products involves multiple stakeholders and numerous data entry and validation points. Project Administrators are tasked with collecting, merging, and ensuring that all changes are properly actioned.

Often, this requires pulling information from various documents for a single SKU, resulting in a time-consuming and error-prone process. Moreover, critical comments and feedback can easily be missed or overlooked, leading to issues that may impact the final product.

IMPACT

Reduce Wasted Cost & Time

Inefficient and inaccurate versioning practices have significant consequences throughout the product and packaging artwork and specification management process. Without automated version control, errors can creep into the artwork and specifications, leading to costly reworks and delays. In addition, the manual nature of managing versions consumes valuable time and necessitates heavy administrative efforts.

Each iteration and revision of artwork and specifications adds time and cost to the project, increasing the risk of launch delays and potentially impacting market competitiveness and revenue generation.